To state the obvious, an engine will not survive long without adequate oil capacity/control. Most OEM engines are designed for RPM limits of 4000 to 5000, many engines not getting close to these limits in everyday driving. At these RPM levels the standard oil capacities are usually adequate.

The problems start when modifying engines for more performance, the obvious result is higher RPM capability. The standard OEM Oil Pans can be totally drained of oil as RPM limits increase.

A crank spinning at 6000 rpm is turning one hundred times each second. At that speed the crankpin in an engine with a 3.5 inch stroke will be traveling in a circle at almost twenty-eight metres a second. If you think about how fast that is you might start to get an idea of what happens to any oil sitting in the pan. The pan capacity, if not increased, is insufficient for the increased demand at higher RPM.

The main benefit of enlarging the lower section, from which the pick-up draws oil into the system, is to increase overall capacity. For a mild engine this is usually enough, but as engines move past these limits Oil Pans need more modifications to the internals to keep up with the engines demand.

The spinning crank generates severe air turbulence and pressure in the Oil Pan. Such turbulence, or "windage", pushes down on the surface of the oil causing it to climb the sides of the pan. A windage tray between the spinning crank and the oil level helps avoid this problem by shielding the surface of the oil from severe windage pressure.

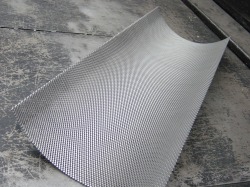

We manufacture Louvered Windage trays to control the oil coming off the crank and direct it back into the pick-up area of the Oil Pan quicker. A combination of enlarged oil reservoir and Windage Tray is the basis for our S/S series oil pans. Most S/S pans also have a crank scraper extending along the recovery side to prevent oil being pushed up the side wall by windage.

The problems start when modifying engines for more performance, the obvious result is higher RPM capability. The standard OEM Oil Pans can be totally drained of oil as RPM limits increase.

A crank spinning at 6000 rpm is turning one hundred times each second. At that speed the crankpin in an engine with a 3.5 inch stroke will be traveling in a circle at almost twenty-eight metres a second. If you think about how fast that is you might start to get an idea of what happens to any oil sitting in the pan. The pan capacity, if not increased, is insufficient for the increased demand at higher RPM.

The main benefit of enlarging the lower section, from which the pick-up draws oil into the system, is to increase overall capacity. For a mild engine this is usually enough, but as engines move past these limits Oil Pans need more modifications to the internals to keep up with the engines demand.

The spinning crank generates severe air turbulence and pressure in the Oil Pan. Such turbulence, or "windage", pushes down on the surface of the oil causing it to climb the sides of the pan. A windage tray between the spinning crank and the oil level helps avoid this problem by shielding the surface of the oil from severe windage pressure.

We manufacture Louvered Windage trays to control the oil coming off the crank and direct it back into the pick-up area of the Oil Pan quicker. A combination of enlarged oil reservoir and Windage Tray is the basis for our S/S series oil pans. Most S/S pans also have a crank scraper extending along the recovery side to prevent oil being pushed up the side wall by windage.

Vertical Oil Control (V.O.C.) Baffles are a standard feature to our Street Comp oil pans.

V.O.C. Baffles are placed in specific locations, acting as a barrier to help control oil movement in pick-up area.

Working in addition with the existing gates and mesh tray, the V.O.C baffles helps provide extra oil control under cornering, braking and acceleration.

Uncontrolled oil has multiple problems;

First, if the oil is not at the pick-up, it can't be drawn it into the system.

Second, as the oil leaves the spinning crank/rotating assembly and bounces off solid surfaces of the Oil Pan it is deflected onto the spinning crank where it creates drag and power loss.

Third, the longer the oil stays in rotation, the more it aerates and collects more heat. You mightn't think that liquid could be that much of a problem, but the speeds mentioned previously there is quite a lot of uncontrolled oil and the effects of it add up.

The Crank Scraper mentioned previously helps control some of this oil bouncing off the vertical walls and directs it back towards the pick-up area. A windage tray is used to control the oil that is leaving the crank/rotating assembly with the intention of directing it back to the pickup area

The most efficient way to strip oil from the rotating assembly in race level high performance engines is to use a mesh style windage tray. This is best achieved by using a Directional Mesh. A Mesh tray allows the oil to pass through easily, but makes it extremely hard for it to come back through because of windage pressure.

First, if the oil is not at the pick-up, it can't be drawn it into the system.

Second, as the oil leaves the spinning crank/rotating assembly and bounces off solid surfaces of the Oil Pan it is deflected onto the spinning crank where it creates drag and power loss.

Third, the longer the oil stays in rotation, the more it aerates and collects more heat. You mightn't think that liquid could be that much of a problem, but the speeds mentioned previously there is quite a lot of uncontrolled oil and the effects of it add up.

The Crank Scraper mentioned previously helps control some of this oil bouncing off the vertical walls and directs it back towards the pick-up area. A windage tray is used to control the oil that is leaving the crank/rotating assembly with the intention of directing it back to the pickup area

The most efficient way to strip oil from the rotating assembly in race level high performance engines is to use a mesh style windage tray. This is best achieved by using a Directional Mesh. A Mesh tray allows the oil to pass through easily, but makes it extremely hard for it to come back through because of windage pressure.

For extreme RPM cases, the solution for oil control at high RPM is to move the side wall of the pan away from the crank, known as a "Kick-Out". Doing so creates a recovery section that catches the oil and allows the oil to recover quickly to the pick-up area. In combination with the modifications mentioned previously, a kick-out is perfect for extra oil control in high performance/ high RPM engines.

The movement of the car itself has an extreme effect on the oil around the pick-up. Braking, cornering, acceleration all force the oil away from the pick-up in different directions.

The idea is to control the oil around the pick-up. This is achieved by using trapdoor baffles or gates that can only swing in one direction - towards the pick-up. ASR positions gates in very specific locations depending on applications. For example, under hard braking any oil around the pick-up won't be able to flow forward because the front gates are closed by the G forces, and because the rear gates open towards the pick-up, any oil at the rear of the pan will flow forward through and accumulate around the pick-up.

The benefits are obvious, a constant supply of oil available to the pick-up during any maneuver no matter how sudden it may be. Another performance modification to oiling systems is the head of the pick-up itself. You'll notice the head of an ASR pick-up is small compared to an OEM unit. The problem is the larger the head the more likely it could become uncovered during use. Making it small increases the likelihood of keeping it immersed in the oil, limiting cavitation problems.

The movement of the car itself has an extreme effect on the oil around the pick-up. Braking, cornering, acceleration all force the oil away from the pick-up in different directions.

The idea is to control the oil around the pick-up. This is achieved by using trapdoor baffles or gates that can only swing in one direction - towards the pick-up. ASR positions gates in very specific locations depending on applications. For example, under hard braking any oil around the pick-up won't be able to flow forward because the front gates are closed by the G forces, and because the rear gates open towards the pick-up, any oil at the rear of the pan will flow forward through and accumulate around the pick-up.

The benefits are obvious, a constant supply of oil available to the pick-up during any maneuver no matter how sudden it may be. Another performance modification to oiling systems is the head of the pick-up itself. You'll notice the head of an ASR pick-up is small compared to an OEM unit. The problem is the larger the head the more likely it could become uncovered during use. Making it small increases the likelihood of keeping it immersed in the oil, limiting cavitation problems.

The main aim of these modifications is to ensure the engine safety, but some of these modifications have shown considerable horse power gains and a substantial temperature reduction over other versions of Oil Pans.